WICKED FAST RESULTS: SAVE TIME AND MONEY

The next-generation solution, this innovative system transforms concrete and cementitious terrazzo floors by simplifying the transition from chemical-free coating removal and stripping to polishing—using water only. Achieve superior results without chemicals, coatings, floor finish, or wax, in less time and with fewer steps—saving money.

- All-in-one system for seamless water-based coating removal, stripping, and polishing

- Superior shine, image gloss, and clarity—no coatings, floor finish, or wax—cuts costs, time, and labor

- Easily maintain highly polished floors with the system’s +1 Shine Tool—clean and polish floors in one step

- Chemical-free—uses water only

- Works on most standard floor machines

RESULTS THAT SHINE

PROGRESSIVE POLISHING: 3+1

Use the System’s 3+1 array of polishing tools to Grind, Hone, Polish and Shine floors. The System’s Shine Tool delivers superior image gloss and clarity, keeping floors looking their best. Clean and polish concrete and terrazzo in one simple step increasing productivity and reducing labor cost.

Polishing System

Grind. Hone. Polish. Shine. That’s the Diamond Devil® system’s 3+1 approach. Three steps vs. the typical 6-step polishing process saves time. This next-generation system’s “+1” Shine Tool takes the finish a step beyond to an unmatched gloss level – using standard floor equipment.

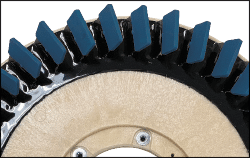

GRIND

Blue – Preps floor with even open finish

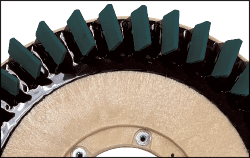

HONE

Green – Sets concrete or terrazzo to a honed finish, ready for polish

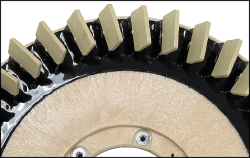

POLISH

Natural – Closes concrete or terrazzo, brings out clean, even satin/polish finish

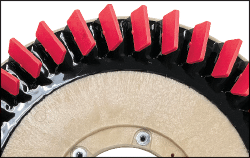

SHINE

Red – Unmatched gloss level using a standard floor machine without chemicals

POLISH PREP TOOL: SURFACE DEMON™

The next generation solution completes The Diamond Devil® Concrete & Terrazzo Restoration and Polishing System.

Use the System’s NEW Surface Demon™ Polish Prep Tool on concrete and terrazzo to remove scratches and light coatings to prep the floor for polish.

For concrete, Surface Demon™ takes floors from Mastic Demon® coating removal to polishing by reducing the deep scratch pattern created by Mastic Demon®, prepping it for polish.

For cementitious terrazzo chemical-free stripping applications: Strip up to 5 coats of floor finish, 2 coats of floor sealer, or 1 coat of urethane—chemical-free, using only water—to prep terrazzo floors for polishing.

POWERFUL COATING REMOVAL: MASTIC DEMON®

A powerful floor restoration tool, the Mastic Demon® cuts into coatings aggressively, leaving an improved surface profile.

Use the System’s Mastic Demon® Tool on concrete for speedy, easy removal of even the toughest coatings from concrete floors chemical-free, including mastic, glue, adhesive, thin-set, paint, thin mil epoxy, and more. Efficient and effective, Mastic Demon® leaves behind an improved surface profile between a CSP2 & CSP3, ready for a recoat or new floor lay. Works on standard floor machines. Patent pending.

UP TO 30% FASTER

Removes mastic, glue, adhesives, and coatings up to 30% faster without the use of dangerous chemicals.

LARGER BLADES

Enhanced cutting power with 75% larger blades that include increased diamond content that leaves behind an improved surface profile.

IMPROVED EFFICIENCY

Boosts productivity with newly designed angled blades, created to cut and eject debris faster and more efficiently.

STAYS CLEAN!

Avoids build-up on blades and completes jobs faster.

NOTE: For use on interior smooth hard-troweled concrete only including, distribution centers, warehouses, office buildings, retail locations, basements, and garages (not for use on outdoor concrete)