Concrete, and concrete-like substances, are a strong and long-lasting material that has been used in construction for over two thousand years. Some ancient concrete structures still stand today, making it a suitable choice for high-traffic areas or spaces where longevity is a priority. The polished concrete we know today was accidentally discovered in the 1990s by workers in Tunisia who were trying to dry a floor and ended up polishing it. Today, polished concrete has become more and more popular for decorative purposes as well as in residential applications. The reason behind this is its strength, minimal maintenance needs, and eco-friendly properties. Advancements in tools and techniques have made it possible to achieve any surface finish from rough to high gloss on concrete floors, and the equipment needed to achieve this has also become more accessible and manageable.

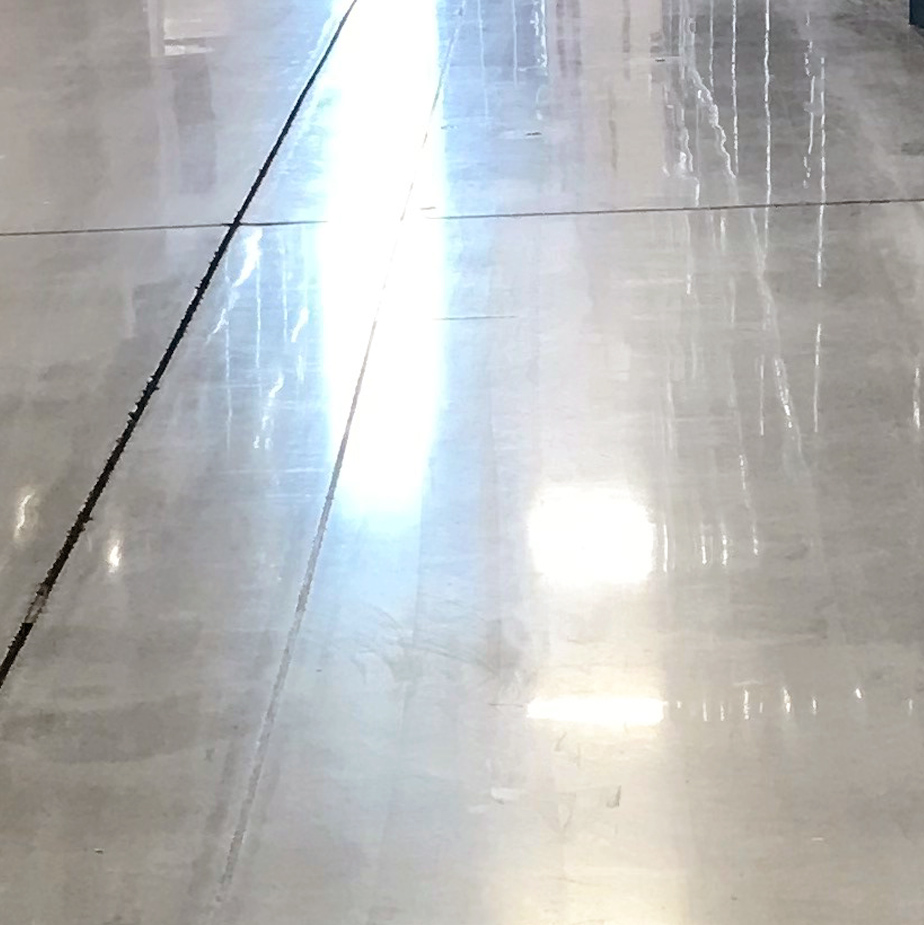

Standard Satin Polished Concrete Unmatched image gloss level using

the Diamond Devil® +1 Shine Tool

Why Polished Concrete Is A Popular Choice

- Concrete is extremely durable—so if your floor has heavy foot traffic or takes a beating, concrete is a great option.

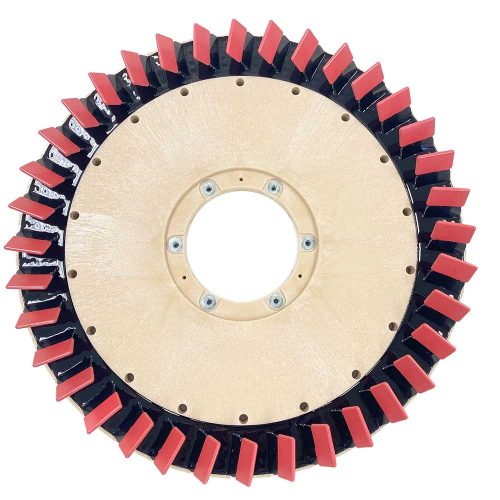

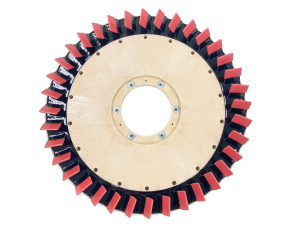

- Low maintenance – once brought up to a polished level, it is easy to maintain as part of a daily/weekly maintenance program, using your standard floor equipment with The Diamond Devil® Red Shine Tool and water only.

- Increase slip resistance – as you use The Red Shine Tool as part of your daily maintenance, the polished concrete continues to be honed, which tightens the pores in the floor improving slip resistance, image gloss, clarity, and DOI.

- Shine without coatings – The Diamond Devil® System does not require any type of coating to produce a shine.

- It is important to note that anytime you add a coating to a concrete floor, it reduces the concrete floor’s natural slip resistance, leaving staff and customers more prone to slips and falls.

Determine Goals for Concrete Floors

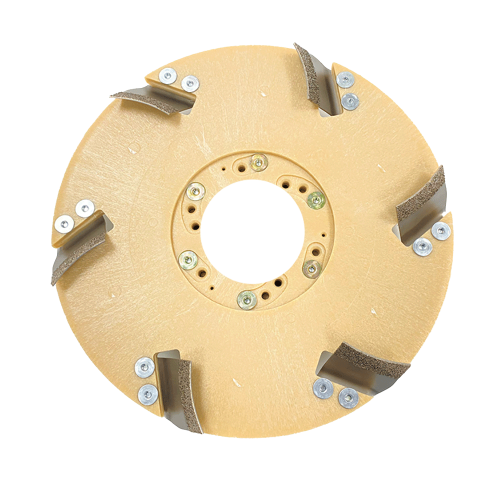

The first step in maintaining your concrete floors is to decide what you want to do with them. Take into consideration whether you require a new floor lay or a recoat, especially if you are dealing with old concrete or if there is an existing coating on the floor. For instance, if you have a sealer or coating, such as—mastic, glue, adhesive, thin-set, paint, or thin mil epoxy—on your concrete floors and want to recoat, we recommend using the Mastic Demon® Coating Removal Tool. If the goal is to transition from coated concrete to polished concrete, start by removing the coating with Mastic Demon®. Then, use the Surface Demon™ Polish Prep Tool to reduce the deep scratch pattern left by Mastic Demon® before proceeding with the first step in the polishing system: the Blue Grind Tool. The Diamond Devil® Concrete Restoration & Polishing System is recommended for anyone whose goal is to have a clean, polished concrete floor. No matter the goal for your concrete floors, there is a tool to help you achieve it.

Intro to Diamond Devil® Concrete Restoration & Polishing System

Innovative Patent Pending System – what sets Diamond Devil® apart from other systems on the market today

- 3 steps vs. typical 6-step polishing process, saving time – to reach a standard level of polish

- Next generation systems +1 (Red) Shine Tool takes the finish a step beyond to an unmatched gloss level – using standard floor equipment

- Chemical-free: works using only water

- Works on standard floor equipment – standard swing machines, walk behind and ride on auto scrubbers

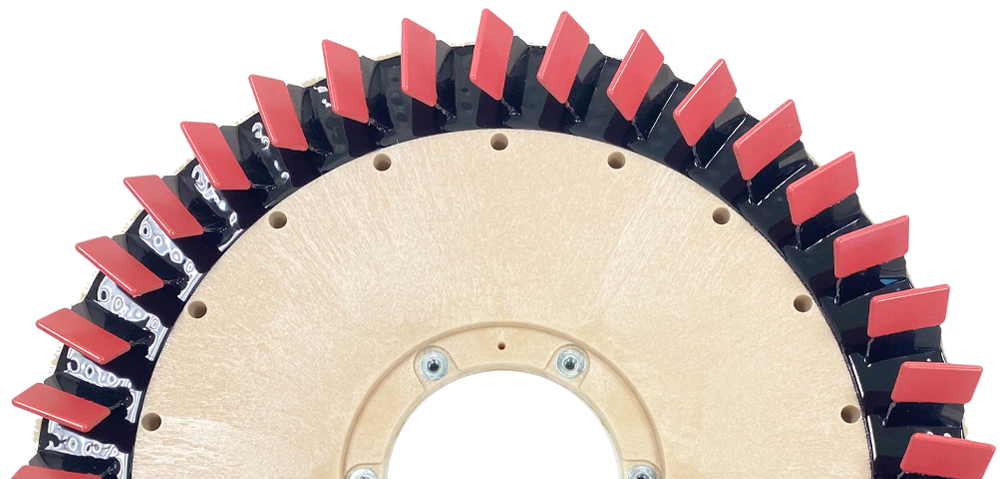

- Permanent blades, that are precisely designed and angled, so no need to stop and replace worn blades

- No pre-use blade hydration required, and no worries about snapping or breaking blades

*NOTE: The Diamond Devil® Concrete Restoration and Polishing System is not recommended for use on decorative, stained, or brushed concrete. Polishing tools should be used only on indoor troweled concrete.

Before starting any polishing project, we strongly suggest working with one of our Diamond Devil® specialists. Contact a specialist today

Equipment

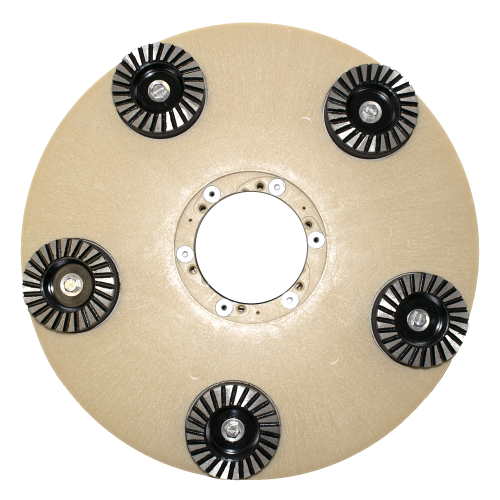

Diamond Devil® Tools are uniquely designed to be used on your existing standard floor equipment instead of renting costly, heavy grinders for coating removal or concrete polishing.

If you’re looking to replace a diamond pad or floor polisher pad used with chemical coatings that require stripping and reapplication, The Diamond Devil® System offers a chemical-free alternative to traditional concrete polishing methods. It delivers superior results while reducing both labor and material costs.

Maintaining highly polished concrete floors is effortless with the system’s +1 Red Shine Tool—it cleans and polishes in one simple step.

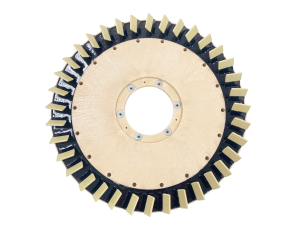

Diamond Devil® Tools

Diamond Devil® concrete polishing tools are part of an innovative concrete restoration and polishing system that works on most standard floor machines, delivering superior results in less time, saving you more money. Achieve remarkable results with the chemical-free, patent pending Diamond Devil® System every time.

Diamond Devil® Tools are available in sizes 12-inch through 20-inch block diameters and fit most standard floor machines.

When ordering tools, auto scrubbers will require the same size Diamond Devil® Tool as the pad driver size recommended for the machine. For Standard Single Disc or low-speed electric floor machines, Diamond Devil® tools can be sized up one size from the recommended pad driver size and ordered with a 1 1/2” riser to accommodate edging.

*Note, risers cannot be used on auto scrubbers.

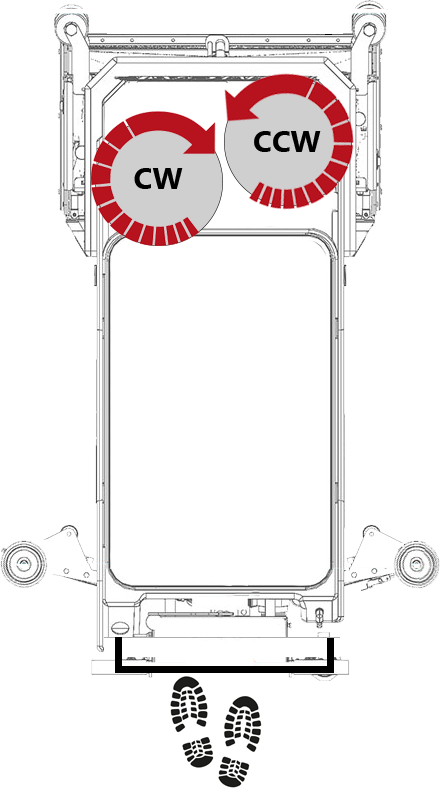

It’s important to note that the Diamond Devil® concrete polishing tools are directional, meaning they either go Clockwise (CW) or Counter-Clockwise (CCW). It’s imperative that the tools are mounted correctly to avoid possible tool or floor machine damage. Install the tools on your machine in the correct direction – ensure the tools are mounted correctly onto the machine from the operator’s view.

Once the rotation is determined, the operator should reference the label printed on top of the tool that specifies if the tool is Clockwise (CW) or Counter-Clockwise (CCW). Typically, low-speed electric floor machines use counter-clockwise (CCW) brushes/tools. However, there are few types of single disc floor machines that are clockwise (CW), so it is suggested to confirm the rotation of the machine before mounting tools.

For dual-headed auto scrubbers, we suggest ordering one CCW and one CW tool as typically one side spins counter-clockwise (CCW), and the other side spins clockwise (CW).

How to know when blades are worn out:

Blade wear can be affected by the condition of the floor. When using Diamond Devil® Concrete Polishing Tools, moving through the steps, if you’re noticing wear on the blades, check for the black wear indicator coming through on the blade as shown in the examples below:

If you see the black wear indicator, make sure to order a new tool. When using the maintenance tool, check wear weekly to ensure the tool is operating at its best.

The Diamond Devil® concrete polishing tools work on standard floor equipment like swing machines, walk-behind and ride-on auto scrubbers. No need to rent heavy-duty concrete grinders or polishers.

Concrete Polishing

How to Use The Diamond Devil® Concrete Restoration & Polishing System

For those wondering how to polish concrete effectively, the Diamond Devil® Concrete Restoration and Polishing System is the answer. This patent-pending system simplifies the process by reducing the number of steps—while still delivering highly polished concrete floors that meet or exceed industry standards.

It is important to know what condition your concrete is in before starting. Concrete polishing is not recommended for all types of concrete floors. Some things to consider when determining if concrete polishing is an option for you:

Is your concrete older and/or in poor condition? Meaning it has a lot of unevenness, cracks, and patchwork.

If yes, then your concrete floor may require another process to be done, either instead of polishing or to be done before polishing can be a viable option.

Newly poured concrete floors should not be polished immediately, as they need to set and cure over time. We suggest waiting at least 28 days to ensure the concrete is cured before using polishing tools.

Questions to consider before reaching out to a Diamond Devil® specialist:

Is it a new pour?

How old is your concrete?

Has it been polished before?

Is there a coating on it currently?

DETERMINE THE CONDITION OF CONCRETE

On a scale from one to six, what is the condition of concrete?

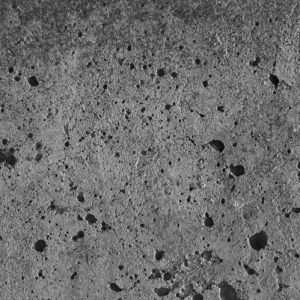

1 – Pitted (If your concrete looks like this, then your floor may require another process to be done either instead of polishing or to be done before polishing can be a viable option)

2 – Coated concrete (Start with The Mastic Demon® Coating Removal Tool)

3 – Rough concrete or concrete that has scratches from Mastic Demon® (Start with The Surface Demon™ Polish Prep Tool)

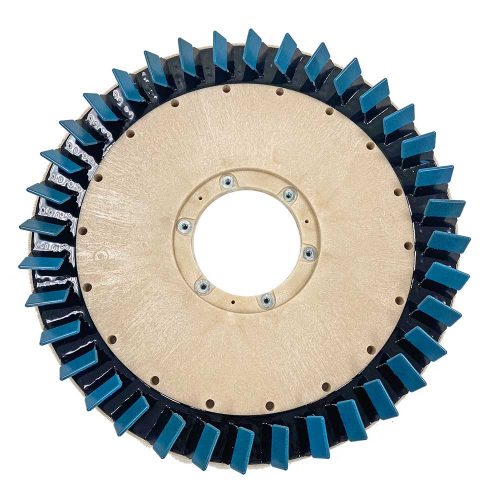

4 –Semi-smooth (Start with The Grind Tool – Blue)

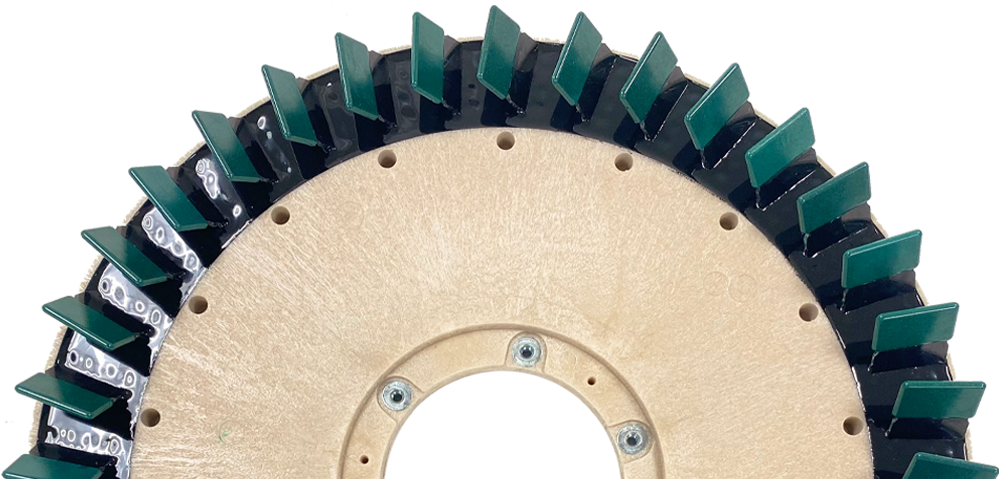

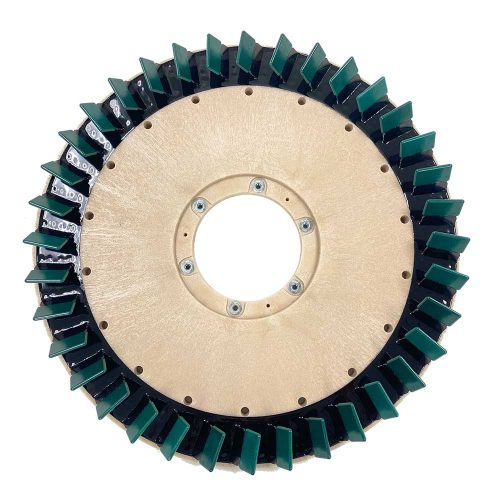

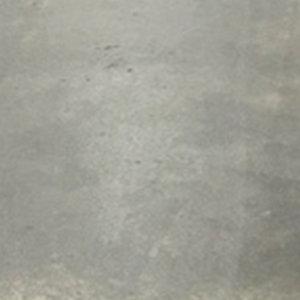

5- Smooth with matte finish (Start with The Hone Tool – Green)

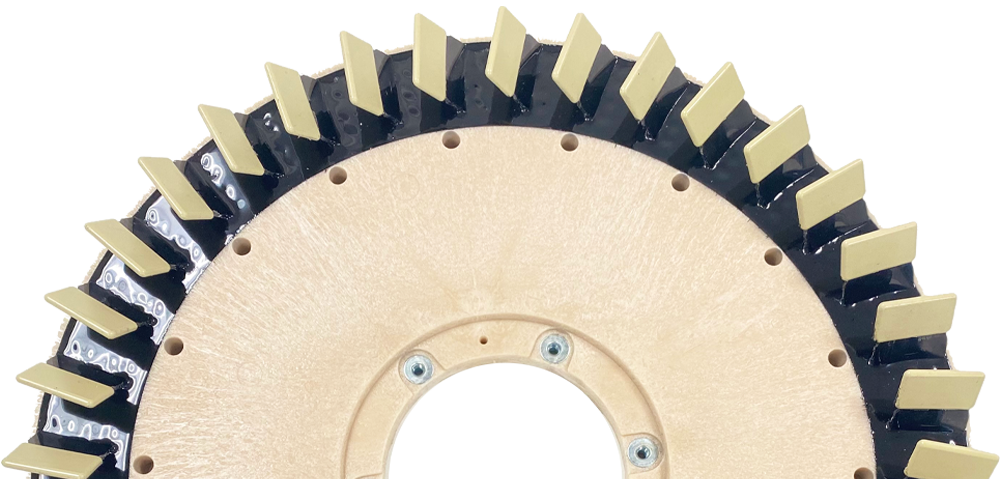

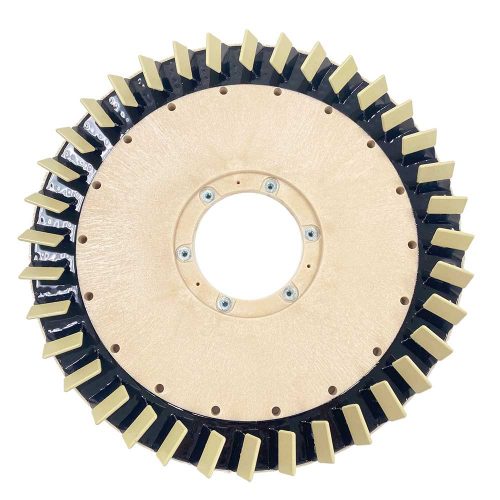

6 – Smooth with some reflection (Start with The Polish Tool – Natural)

7 – Smooth with reflection (Start with The +1 Shine Tool – Red) Takes the finish beyond to an unmatched image gloss level

We recommend consulting with one of our concrete polishing Diamond Devil® specialists today

It is recommended that 6 passes are done with each tool in the system: Grind, Hone, and Polish – this will take your floor to a standard satin polish.

Use the +1 Shine (Red) Tool if you want to elevate the image gloss level beyond industry standards.

The Diamond Devil® Polishing System is not recommended for use on decorative, stained, or brushed concrete. Polishing tools should be used only on indoor troweled concrete.

The Diamond Devil® System’s 3 +1 approach – start with:

-

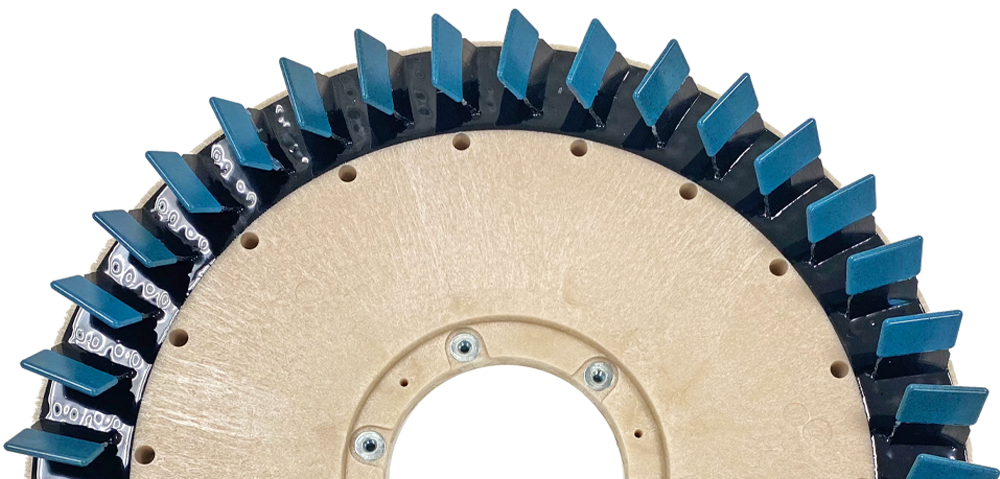

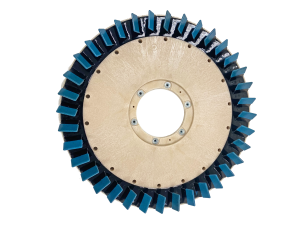

- Grind (Blue) Tool used to prep floors with an open finish

-

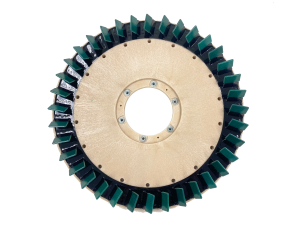

- Hone (Green) Tool used to set concrete to a honed finish, ready for polish

-

- Polish (Natural) Tool closes concrete and brings out a clean “standard” satin/polished finish

-

- +1 Shine (Red) Tool takes the finish a step beyond to an unmatched image gloss level using your standard floor equipment

- Use the +1 Shine Tool for daily or weekly maintenance to clean, polish, and enhance DOI image gloss—all in a single step that continues to improve over time

- +1 Shine (Red) Tool takes the finish a step beyond to an unmatched image gloss level using your standard floor equipment

How to reach the edges of your concrete floors – Edges can only be done using a low-speed electric floor machine (buffer type) because you can oversize tools to extend outside the machine deck, which you cannot with an auto scrubber.

Oversizing tools for floor machines requires a riser.

For example: Use a 17″ tool with a 1 ½” riser and clutch plate for a 17″ deck floor machine; A 20″ tool with a 1 ½” riser and clutch plate for a 20″ floor machine.

How to make concrete floors shine – The Diamond Devil® Concrete Restoration and Polishing System uses a progression of tools Grind, Hone, and Polish that take concrete floors to an even “standard” satin/polished finish. The optional +1 Shine Tool takes the finish a step beyond, to an unmatched superior image gloss and clarity.

Note: All Diamond Devil® Tools can be used on standard swing machines and auto-scrubbers.

Commonly asked questions:

How long does it take to restore (grind) and polish your concrete floors?

The time required to restore and polish concrete floors varies depending upon the condition of the concrete floor, along with the square footage. The Diamond Devil® Concrete Restoration and Polishing System is 3 steps -vs- the typical 6-step polishing processing. Less steps, less time on the floor saves time and money. Before starting any concrete polishing project, we strongly suggest working with one our Diamond Devil® specialists. Contact a specialist today

Can I go from coated concrete to polished concrete?

Yes! With The Diamond Devil® Concrete & Terrazzo Restoration and Polishing System, you can transform your concrete floors from coated to polished. Start by removing the coatings with The Mastic Demon® Coating Removal Tool, then use The Surface Demon™ Polish Prep Tool to reduce deep scratches created by Mastic Demon®. Finally, proceed to the first step in the polishing system with The Blue Grind Tool.

Should I use densifier?

Densifier can be used but is not necessary when using the chemical-free Diamond Devil® Concrete Restoration and Polishing System.

Can I use cleaners with the Diamond Devil® System during daily maintenance?

Yes, a neutral cleaner can be used, but we recommend using only water with the chemical-free Diamond Devil® Polishing System.

How does The Diamond Devil® System compare to a Diamond Pad or Floor Polisher Pad?

The Diamond Devil® System outperforms traditional diamond pad and floor polisher pad systems by requiring significantly fewer steps and eliminating the need for chemicals. Unlike other systems that rely on chemical coatings or topicals to achieve and maintain the shine, Diamond Devil® uses only water during the polishing process—no harsh chemicals or coatings are required. Plus, using our +1 Red Shine Tool for daily/weekly maintenance, you can clean and sustain a high-gloss finish and DOI in one step without being dependent on chemical applications for the life of the floor.