As a warehouse manager, maintaining clean and safe floors is crucial for operational efficiency and safety. This article provides some DIY floor care hacks to keep warehouse floors in top condition, using an effective and eco-friendly method.

Many systems claim to polish concrete floors effectively. However, often costly heavy concrete grinding equipment or gallons of chemicals, coatings, and a multitude of floor pads are necessary. And these methods are just sufficient with short-lived results.

There’s a better option: The Diamond Devil® Concrete & Terrazzo Restoration and Polishing System. This system is more effective and efficient. The system significantly enhances the appearance and durability of warehouse floors without heavy equipment, chemicals, coatings, or floor pads.

The Diamond Devil® System delivers superior image gloss and DOI (Distinctness of Image) using only water and existing floor equipment. Anyone who knows how to operate a floor machine can polish concrete floors!

Here’s a step-by-step guide for DIY concrete polishing:

Materials needed

-

- The Diamond Devil® Concrete & Terrazzo Restoration and Polishing System includes a set of four tools:

– Grind Tool

– Hone Tool

– Polish Tool

– +1 Red Shine Tool

- Existing standard floor equipment: Auto scrubber, ride-on, walk-behind, or single disc machine

- Accessories: Malish Splash Guard™

- Water: Diamond Devil® is a chemical-free system that uses only water

It’s important to know the current condition of the concrete before getting started. Polishing might not be the best option for all types of concrete floors. To confirm if the concrete’s ready to be polished or for other assistance, contact one of our Diamond Devil® specialists. Here’s what’s important to evaluate before beginning:

-

- Is the concrete older and in poor condition? Does it have cracks, patched areas, or unevenness?

– If yes, the concrete may require another process before it can be polished.

-

- Is the concrete floor a new pour?

– If yes, it’s recommended to wait for at least 28 days to allow it to fully cure before polishing.

-

- Is the concrete polished already but doesn’t have a high shine and DOI expected?

– If yes, it’s recommended to begin with the Hone Tool, then proceed with the Polish Tool to reach a standard satin polish. Continuing with the +1 Red Shine Tool will take the finish a step beyond to an unmatched image gloss level.

Steps to polish concrete floors:

1) Prepare

- Clear the area. Remove all items from the floor, including furniture and machinery.

- Clean the floor. Sweep the floor to remove any debris.

2) Inspect. Check the floor for cracks, holes, or uneven areas. Repair any significant issues before beginning the polishing process.

3) Begin polishing. It’s recommended that six passes are done with each tool (Grind, Hone, Polish) during the process to produce a standard/satin polish. The +1 Red Shine tool is an optional final step to be used to elevate the image gloss.

Here’s what The Diamond Devil® Tools deliver:

- Grind Tool. Removes light coatings and preps the floor with an open finish.

- Hone Tool. Used to set concrete to a honed finish, ready for polish.

- Polish Tool. Closes the concrete bringing it to a standard/satin polish.

- +1 Red Shine Tool. Elevates the floor to the next level producing an image gloss that’s beyond industry standards. This also becomes the maintenance tool and each time it’s used the DOI and image gloss level continue to improve.

Tips for success:

- Take your time. When completing six passes with each tool, proceed slowly. Rushing through the process can impact the DOI achieved on the floors.

- Maintain with ease. Use the +1 Red Shine Tool for ongoing maintenance to clean and polish concrete floors without chemicals or coatings.

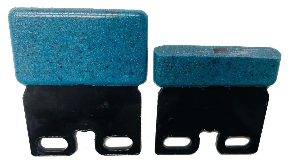

- Know when to replace the Red Shine Tool. When the black wear indicator comes through inside the blade (see image below) it’s time to order a new tool.

- Safety first. Wear appropriate PPE, especially when handling machinery and chemicals.

- Test in a small area. Before starting, test the system on a small inconspicuous area to get a feel for the equipment and process.

- Equipment maintenance. Regularly inspect and maintain your standard floor equipment to ensure it operates efficiently. Keeping a maintenance log can help you track when each piece of equipment was last serviced, ensuring nothing is overlooked. Simple tasks like checking for worn parts can prolong its lifespan and improve performance.

Polishing a concrete floor can be a rewarding DIY project that gives a warehouse a professional and durable finish with a shine that has a reflective quality—without the expense of heavy concrete polishing equipment or costly epoxy and other coatings.

Conclusion

Imagine walking through the warehouse and noticing the floor’s shine and reflection– free of epoxy, sealer, wax, or other coatings. Just concrete, highly honed and polished (using only water and existing floor equipment). Maintenance is a breeze with the Red Shine Tool and water, again using existing floor equipment. No more expensive and time-consuming maintenance projects.

Reduction in products and labor time means the Diamond Devil® System results in cost savings immediately and over time. By investing in the right polishing system, you can easily maintain polished concrete floors with superior image gloss and reflective shine. This contributes to a safer, more efficient, and pleasant work environment for everyone.

There’s a safety aspect also: cleaner floors, void of any epoxy, sealers or other coatings mean fewer slip-and-fall incidents. Plus, a clean warehouse reflects positively on the business, showcasing a commitment to high standards and care for employees and products.

For more detailed information on achieving superior results polishing concrete floors, contact Malish today to schedule a free, on-site demo of The Diamond Devil® System. Malish, a leader in floor care solutions since 1945.